PYROLYSIS ------WHAT IS PYROLYSIS-------TIRES-------PLASTICS

Pyro = heat. Lysis = break down.

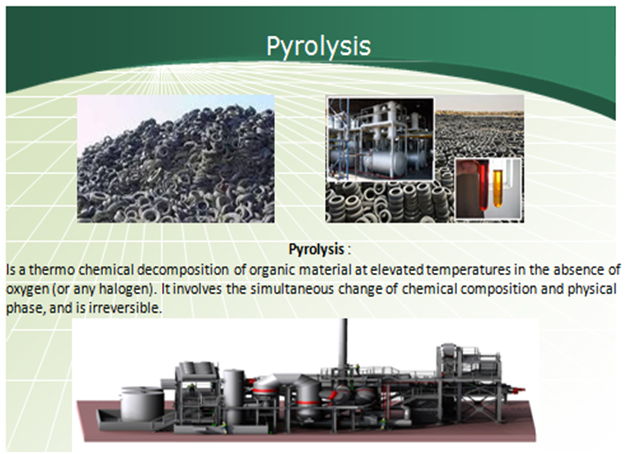

Pyro = heat. Lysis = break down.Pyrolysis is chemical reaction. This reaction involves molecular breakdown of larger molecules into smaller molecules in presence of heat. Pyrolysis is also known as thermal cracking, cracking, thermolysis, depolymerization, etc.

At any given temperature the molecule is in vibrating stage. This is called molecular vibration. The frequency at which molecules vibrates is the directly proportional to the temperature of molecules. During pyrolysis the object's molecules are subjected to very high temperatures leading to very high molecular vibrations. At these high molecular vibrations, every molecule in the object is stretched and shaken to such an extent that molecules starts breaking down into smaller molecules. This is pyrolysis.

Simplest example of pyrolysis is food cooking. When you cook food the temperature of food increases leading to higher molecular vibrations and breakdown of larger complex molecules into smaller and simple molecules. After cooking larger food molecules are pyrolyzed into smaller in simpler molecules which are easy to digest.

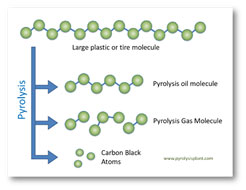

What is Plastic and Tire Pyrolysis ?

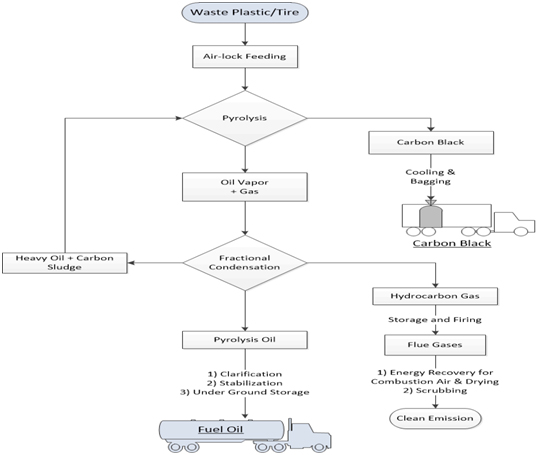

Plastic and tire pyrolysis involves subjecting plastic and tire to high temperature of 400 to 450 degree Celsius, in absence of oxygen. In case of oxygen is present plastic will start burning. During pyrolysis plastic and tire breaks down into smaller molecules of pyrolysis oil, pyrolysis gas and carbon black. Like plastic and tire, pyrolysis end products are also hydrocarbons. Pyrolysis is great way of recycling waste plastics and tires. Given below are benefits of waste plastic and tire pyrolysis.

• Recycles synergy of waste plastic and tire into usable fuel.

• Offers renewable energy source.

• The in product can be used as fuel in existing industrial boilers and furnaces. End products can also be used for generating electricity.

• Eliminates hazard of land pollution by waste plastics and tire.

• Converts waste into energy.

• Clears dumping yards and environment of non bio degradable plastic and tire waste.

Pyrolysis plant falls under following categories of industrial projects:

• Waste to energy project

• Waste plastic and tire pollution control equipment

• Renewable energy project

• Petrochemical

We establish large scale pyrolysis plants on turnkey basis . The total turnkey supply includes of machinery designing & simulation, equipment manufacturing, supply, installation, commissioning, technology transfer and operational training.

Advantages of pyrolysis plants manufactured & supplied by GAC Systems:

• Purest quality of pyrolysis oil as finished product

• Use of green technology to achieve Environment friendly processes

• Both plastic & tire can be used as raw material

• Continuous type pyrolysis process

• Breakthrough technologies used to improve safety, profitability & ease of operation

• More than 90% of machinery parts are non-moving: this reduces the recurring maintenance.

• Proven machinery and technology.

• Industry is energy self-sufficient

• No external fuel required for heating

Following diagram shows the typical process flow.

Industrial pyrolysis of waste plastic and tires.

Industry that converts waste plastic and tire into pyrolysis products like pyrolysis oil, pyrolysis gas, carbon black is called pyrolysis plant. Pyrolysis plant offers new business opportunities like:

• Recycling

• Waste to energy

• Waste to electricity

• Energy recovery from waste

• Solid waste management

• Pollution control

• New and renewable energy

• Environment protection

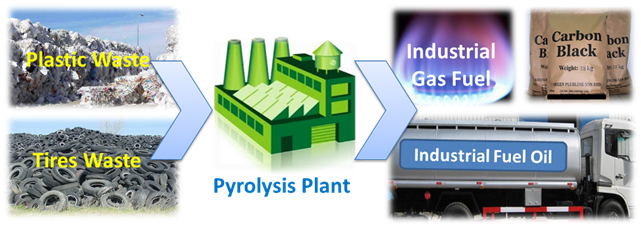

Today's world generates millions of tons of waste plastic and tires every month. Plastic and tyre pyrolysis can convert this waste into energy worth billions of dollars. Pyrolysis plant is an upcoming industry that will fuel tomorrow's growth and protect environment by cleaning dumping yard off waste plastic and tire.

Pyrolysis plant is an industry that converts waste plastic & tires into Pyrolysis Oil, Carbon Black & Hydrocarbon Gas.

End products are used as industrial fuels for producing heat, steam or electricity. Pyrolysis plant is also known as: pyrolysis unit, plastic to fuel industry, tire to fuel industry, plastic and tire recycling unit etc.

Pyrolysis oil is the end product of waste plastic and tyre pyrolysis. Pyrolysis oil is widely used as industrial fuel to substitute furnace oil or industrial diesel. Typical industrial applications of pyrolysis oil as a fuel:

• Boilers

• Furnaces

• Hot Water Generators

• Hot Air Generators

• Thermic Fluid Heater

• Electric Generators (mixed with 50% diesel)

• Diesel Pumps(mixed with 50% diesel)